But a better cause for celebration is that my printer finally arrived. (that I ordered in JULY with a promise of 8 - 10 weeks shipping)

Given that I live in the UK and it's November 5th, that also means that my celebration blog post and Solidoodle arrival will be met with actual fireworks, (though technically not for celebrating the fact that I finally have a 3d printer!)

So I thought in the interests of anyone still waiting for theirs, (and anyone considering ordering) I thought I'd write something about my impressions of the printer.

I guess the first thing to do is get the biggest complaint out of the way first.

Ordering/Waiting/Shipping:

I ordered my printer on July 13th, and was told that there would be a 8-10 week wait.

16 weeks later I was still twiddling my thumbs...

It was November 3rd when I finally got my printer.

My printer appears to have shipped out of order, and there doesn't seem to be a reason for this, (support have said that the order was not expedited).

From my point of view, I was not an early-order-er. I ordered after the machine was in production and had started shipping.

I was made a promise that it would be 8-10 weeks, then was made more promises via the publicly released shipping updates time after time, that were also broken.

Support:

I only contacted support I believe 3 or 4 times, (and one of those times was to ask for a tracking number)

Generally, I found support to be quick to respond, (when contacted via email), but also fast to make promises. Initially their promises about shipping seemed completely at odds with what was being said publicly, (as in they were offering faster shipping times than the already seemingly unrealistically fast shipping notices that were being released), but they did come through on that promise.

my only two problems with contacting support were:

Queries made via the web form on the solidoodle site were completely ignored.

(I know that the queries are monitored as my pre-sales queries were answered using this form).

Secondly, one email was either lost, or ignored.

Thankfully, I've had no issues since I got my tracking number, but I do have to say I am not relishing the idea of having to contact support, not knowing if my emails have gone missing, I'm in a different time zone, (different continent even) so I don't expect instant replies. but that does also mean that if I send a message I won't know if it's lost or ignored for a few days.

So far as the whole experience those are my only two gripes.

and I can sum it up in just one word. COMMUNICATION,

I really hope that communication improves, that is, that communication about shipping becomes more accurate, that decisions that seemingly don't make sense are communicated more effectually. and really, I hope that if emails are going missing with such frequency, that you guys get a better email provider.

The facts are I'm happy with my machine, (as you'll find out as you read below), but given the communication issues, personally I wouldn't recommend buying this printer to a friend. Perhaps when things are settled and sorted, the back order is completely cleared etc, then I'd recommend a friend buys one, but I don't want to be the reason for someone getting caught up in the current fiasco! having to worry about if they are ever going to get their printer, worrying about if they can even believe what the support people are telling them about the printer.

To be honest an extra six weeks wait actually seems a bit trivial (now that I have the device) but it's the lack of communication that really irked me.

Import duties:

For anyone interested, import fees to the UK were £93.22 (~$148 USD) there is no duty to pay on the machine, the fees are made entirely of VAT (Sales Tax) and processing fees from the post office.

Now only the machine:

Packaging:

There have been a bunch of complaints about packaging, and people getting machines that have been broken, support said some time ago that they would be changing the packaging set-up, and I believe that what they have done has been a brilliant improvement.

Firstly, the outside box was a decent size of card, (about 1/4" corrugated) there was no damage to this

the inside of the box was packed about 3" deep in every direction with Styrofoam peanuts.

the printer was then wrapped in bubble wrap.

the plexi-glass door was covered in a brown plastic coating, (from the manufacturer) and so had absolutely no scratches.

unpon taking the machine out of the box...

the print head appeared to be centred, and bubble wrap had been rolled into little tubes which supported the print head, the bed and all the moving parts.

the roll of filament was inside the machine (under the bed which was raised to the top) and also held in place with rolls of bubble wrap.

Shipping the filament inside the box was a great thing for me, if only because it meant that not only did the filament arrive WITH the printer, - so I was ready to go, it also meant that there was no second box to worry about, no second duty fees, no second postal service fees for the import, and no second drive to the post office.

Considering that some machines couldn't get across the states without coming to pieces, and yet with this new packaging regime this printer has managed to get.

across the state, onto a boat, across the Atlantic, (on the storm front of a hurricane), then across Britain, through various depots, etc, this appears to be a huge improvement!)

So for packaging, I can only offer a ten out of ten!

What's in the box:

inside the box, there is a power supply cord. - it's got a European rather than UK plug on it, but that's not a problem the plug on the machine is a C5 connector and so I've plenty of spares laying around.

there is some paper, telling you what's in the box, your order inventory, a sheet saying welcome to the solidoodle family (a nice if not cheesy touch).

There was a small roll of starter filament.

when I say small roll.

there were reports that some people got a test length of a few inches...

like that.

approximately enough to fashion a new teste for a gnat.

however, there was a generous roll of starter filament,

There was no tool kit, (this was listed on the order form when I ordered that I'd get a printer and a free tool kit containing all the tools I'd need -small scrapper/hex wrench/little brush for cleaning the machine)- but I do have more than enough tools of my own.

tools I'd think that a person could want are

1x 2.m mm hex wrench

1x cross head screwdriver (for removing the case)

1x craft knife for cutting and trimming printed stuff

1 x craft knife with chisel blade for popping prints off the platform.

(for day to day use)

and if you have delicate fingers maybe some tweezers.

- I can't say what tools you're going to need to strip down and rebuild your machine because I haven't done that yet!

To set the machine up I used some regular auto mechanics type feeler gauges. these are really cheap.

as for the tweezers, I generally don't have a problem with touching hot things, - years of burning myself with soldering irons appears to have dulled my senses, so i've been pulling and seeped out or built up plastic off the hot end with my fingers.

Weirdly also in the box was a random m3 nut. it was stuck to the doors protective layer.

When I came to remove the case to install the filament, I found that there was an m3 bolt missing. -not an issue I have plenty of these, but does show a bit of a lack of detail.

Set Up:

The software install instructions are remarkably easy to follow. - I followed the ones on the solidoodle website.

They are literally step by step from opening the box to printing, the only thing that was missing was the instructions appeared to go straight from install this software, to this is how you print. ignoring details on how to level the bed.

Levelling the bed is however pretty straight forward. in fact so straight forward I just figured out how to do it myself.

First I moved the X motor forward and back, and hit X home. - it went the right way.

then I moved the Y forward and back then hit Y home, - it also went the correct way.

same approach with Z, when Z finally homed to seemed apparent that had I decided to start with this axis I'd have a hole in my kapton, and a bent extruder.

so I altered the z-stop.

Then we come to the actual bed levelling.

it's easy enough to level the bed, I use proper feeler gauges, (which I imagine made it easier.)

It took about two minutes to level all four corners.

but then I had the idea to run the extruder over the length of the build area, clearance ranged from a very tight 0.3mm to loose 0.4mm not a huge amount of deflection. (I could measure exactly, (either with feeler gauges, or using a dial gauge -which I bought especially for this machine! -but didn't [yet]).

Printing:

for my test print I decided that I should print something that would be easy to measure, have some height, involve a complex shape (round), and of course something that I could print to appease the missus for the large amount of money that I'd just spend on a toy.

I went with a heart shaped box

printing was pretty straight forward, I left everything on default settings, (so there is a raft), the printer zeros to the bed middle, and then prints in the top corner.

-weird, the y axis homing direction appears to be fixed, but not the start position co-ordinates.

printing happens exactly correctly first time.

and second time.

and third time.

and they fit together.

the print measures just fine.

default settings, out of the box, the solidoodle seems pretty well dialled in, the round parts seem round.

the width is the 40mm is should be, the wall thickness is 2mm over the whole shape.

the box lid is printed and is exactly the correct size, (a tolerance fit) to the box. and includes a 2mm overhang of 90degrees/0 degrees (depends where you measure from). - which the printer coped with very well.

further printing

printing more things however does show up some problems in this printer.

I don't need a raft for example, but when the raft is removed, I find that it is difficult to ensure that the first layer extrudes properly, a little more pre feed is needed from the default profile, (this also means a tiny section of the raft is also missing, but that never shows up as a problem).

the second problem is, whilst the bed deflection is pretty minute at a tenth of a millimetre, this does mean that printing can become problematic, the middle is raised high, so prints stick here very well, and yet have great trouble sticking at the edge.

Then there is the problem of heating.

Seriously, I feel I need to turn on the machine, then watch some tele, make a coffee, eat dinner then it might just be ready to heat. The bed has the 0 - 100 performance of my first car. (which was French, and shite).

Another issue, the heat does not spread evenly across the bed.

I printed a small round shape with a star shaped hole through it,

at the centre, the print was so warm on the bed that it was distorted. (-but glossy smooth)

at the edges, there was so little heat that it has trouble sticking and strands were clearly visible. -though bed height may have been an issue here also.

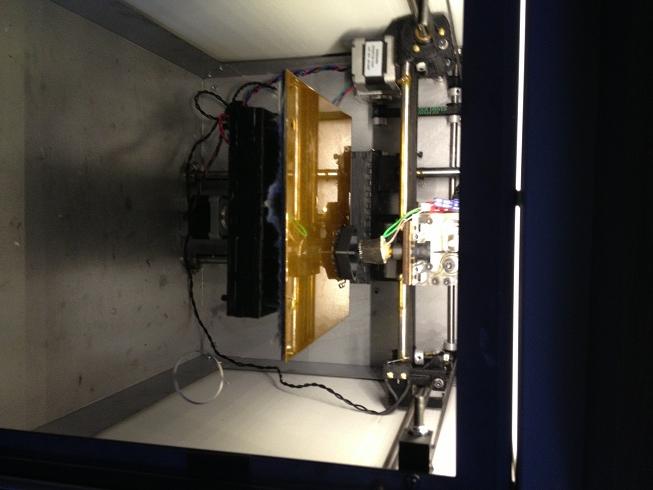

Machine Design:

Over all I think that the machine is designed exceptionally well, everything holds together neat and tidy, it's astonishingly quiet, I expected it to be about as loud as a standard ink jet printer, but can happily say it seems quieter, and the noise that it does make is not as monotonous as an inkjet printer either!!

It looks like it'll take some abuse, the steel frame is very well put together, I've not tried standing on it, but I believe the claim that it would support an adult standing on it!

The machine looks deceptively simple, and I imagine will be very easy to maintain.

I think that the strong frame really sets this machine apart from other machines but at the same time it looks like it really reduces the amount of space that there is to work inside the machine. - I mean there isn't a lot of space for bolt on modifications.

So all in all, I'm very happy with my machine.

There are a couple of snags:

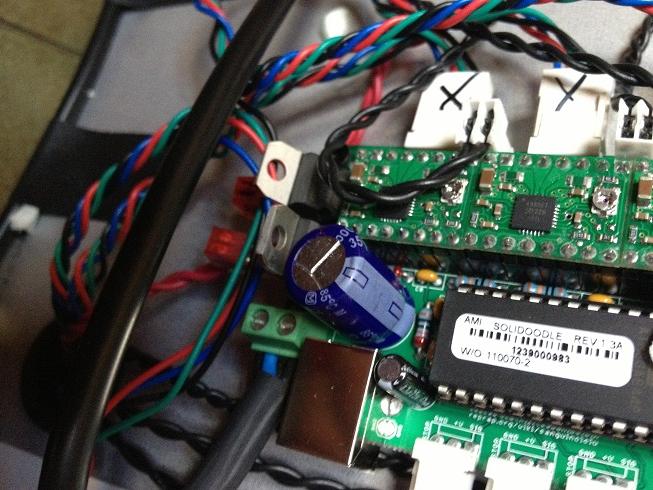

The first is that the circuit board is very exposed, in shipping some of the components had bent, I've bent them back, but I obviously don't want to constantly be bending component legs cause they'll fatigue and snap.

A cover will fix this, and this will be high on my list of things to print.

(I'm also going to get some cable management to sort that lot out!!)

Second, the x stop switch leads rub against the side of the case, the case has a rough texture so eventually this will wear through the leads.

as a temporary fix I've put some parcel tape on the inside of the case. this doesn't stop the rubbing, but does at least provide a smooth surface so the rubbing should not be a problem. - though I may investigate some cable routing in the future.

Third, loading the filament is a bit of a mission with the case on. it's not a problem to remove the case, but I'm thinking of installing a hatch in the top for easy access.

Fourth the bed. as I said above, it's not level, does not heat at all evenly and takes ages to come up to temperature. I believe that the fix for this is going to involve.

A relay, a second power supply, nichrome wire, and a sheet of glass.

Fifth and finally.

Communication.

I'm not completely sure that the pretty sour taste of my first third of a year of being a part of "the solidoodle family" will ever truly leave me.

so all in all.

Is the machine perfect?

No, but it's pretty darn close, and for the money it's amazing...

If you want to print out generic tat -like the heart shaped box then it'll suit your purpose. if you want to try printing small parts with some intricate details you're going to need to fettle things.

No comments:

Post a Comment