During the time that I'm waiting for my new printer to arrive I'm going to be re-familiarising myself with using CAD software ready so that I can make things on my printer when it gets here.

I can't see 3D CAD lessons being a regular thing like the electronics and code lessons, because it's just one piece of software. there is only so much that can be shared.

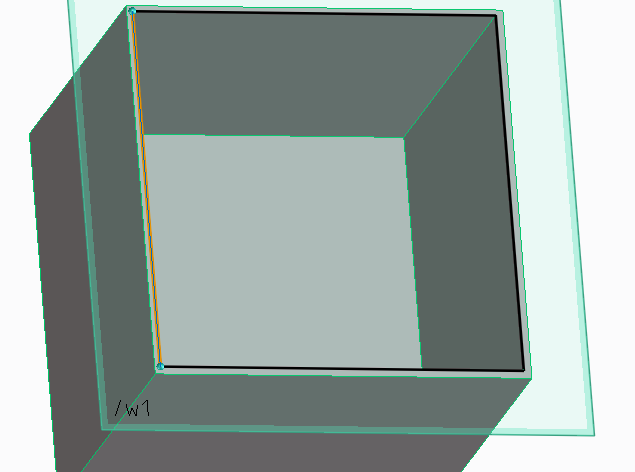

Calibration cube.

One of the first things that should be printed on any 3D printer is an object that you can use to calibrate the printer and settings in the software.

Having your extruder running too fast and squishing out too much plastic will lead to your layers being too fat, and plastic being squashed outwards meaning that your parts appear bigged in out edges and smaller where holes are concerned.

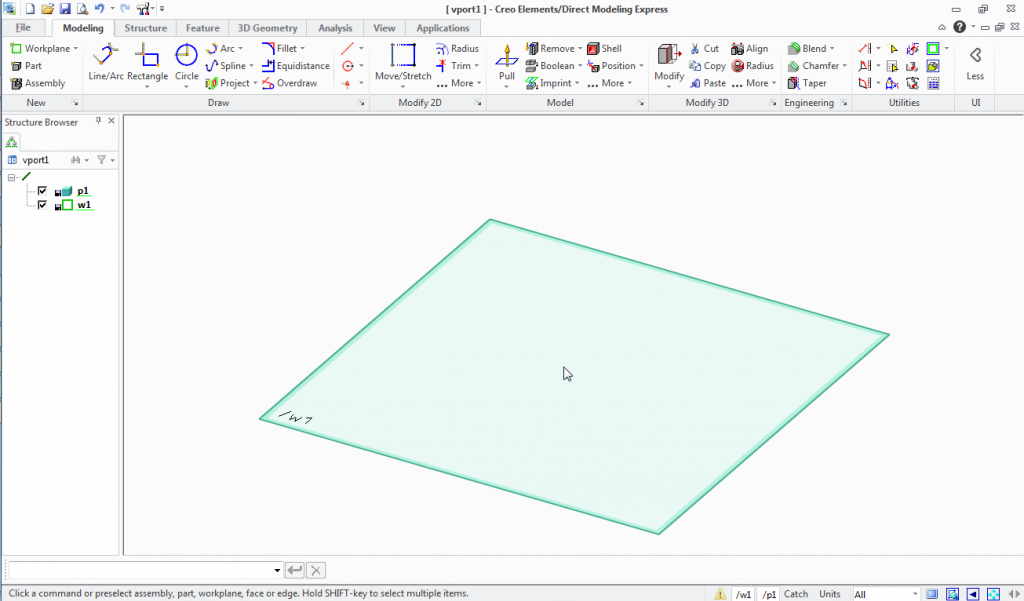

First, open the software, you are presented with a screen that has a blue diamond on it. that's actually a rectangle that's representing your build plane, it's got some perspective about it.

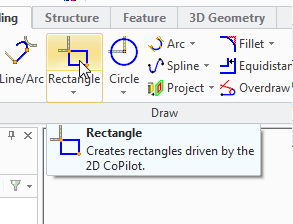

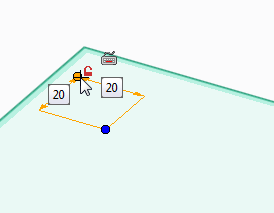

Click anywhere on your build platform, and drag out a square, the small numbers that appear at the

edges tell you how big the square is.

now the square turns black.

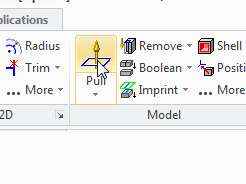

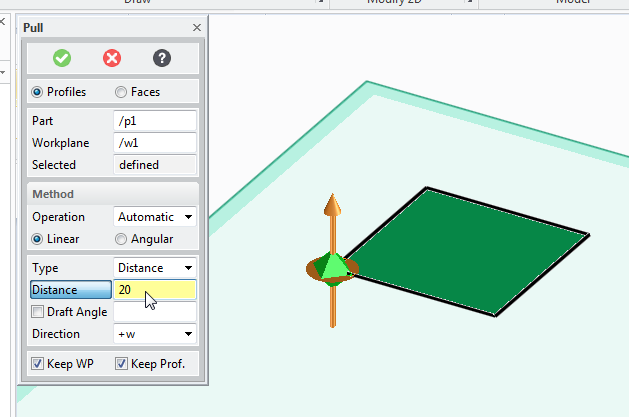

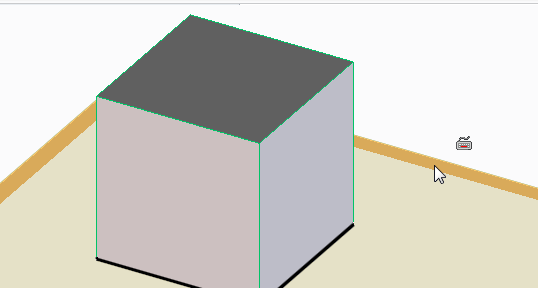

go to the menu bar at the top and select pull

Click at the dark blue edge of the work-plane so that it is highlighted brown, now press the delete key you're left with a cube in the centre of the screen.

Now you want to turn your cube into a tube.

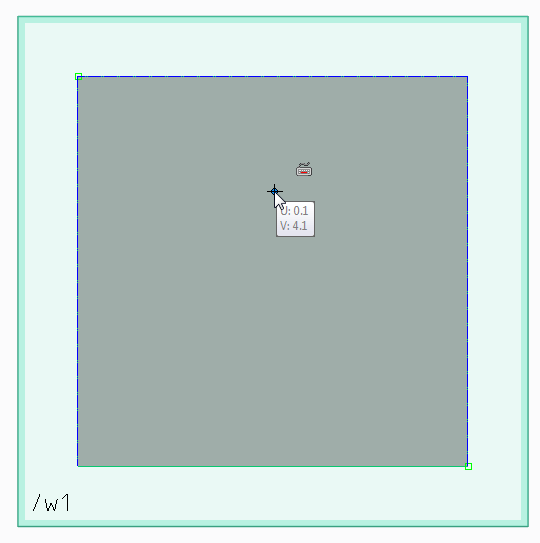

so click on the rectangle tool again, and the click on the top face of the cube, (anywhere on the top face)

the cube now rotates so that you're looking at the very top, zooms so that the face fills the screen, and generates a new work plane for you on the axis that you want.

move the mouse around, you'll find that as you;re moving around co-ordinates appear that tell you how far from the edge you are, or how far from the middle.

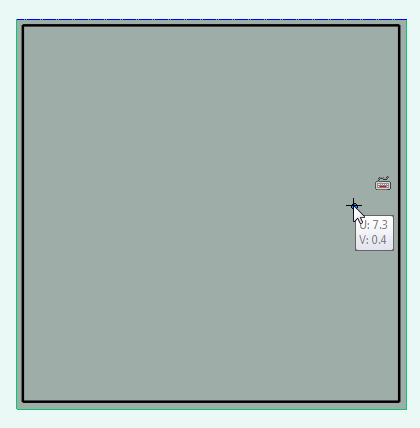

The nozzle on the solidoodle is 0.3mm wide, therefore is we create a wall thickness much more than this, the machine will try to do two passes and make a double thickness wall, but it won't be twice as thick exactly, so we will miss some vital data regarding extrusion width which will be used to help calibrate the flow settings.

click on the box 0.3mm from one corner, and drag a new square to the opposite corner.

In the distance box type -20 to create a tube, or -19 to create an open box that has a bottom face.

I'll cover how to actually use the box to calibrate a printer in a post when I've actually got the printer.

No comments:

Post a Comment